A guide in choosing

Putting pizza in or taking it out?

Gi.Metal pizza peels are designed to take pizza from the work counter and to place it in the oven. They have different sizes and shapes to adapt to the different pizza variants and lengths suited to different work spaces. The small peels are handy and precise to manage: they allow you to turn the pizza inside the oven, to check baking by lifting the bottom and to take it out when ready.

Perforated or solid?

We are the first company to have invented, designed and made the exclusive perforation for pizza peels, a very important innovation that makes the pizza maker’s job easier. Gi.Metal dedicates the same attention who prefer a traditional solid pizza peel, with a wide range of perfectly efficient items.

The advantages of the holes

Maximum smoothness: very low friction. The holes are blunted and rounded at the cutting ends, so that even moister dough slides in a trouble-free way.

Lightweight: the perforated blade has less material and therefore weighs less.

Less smoke: less flour burning means less smoke in the room.

No more burns or bitter tasting pizza: burning flour below the pizza creates black burns and makes it taste bitter.

Cleaner: less burnt flour in the oven means less need to clean the surface.

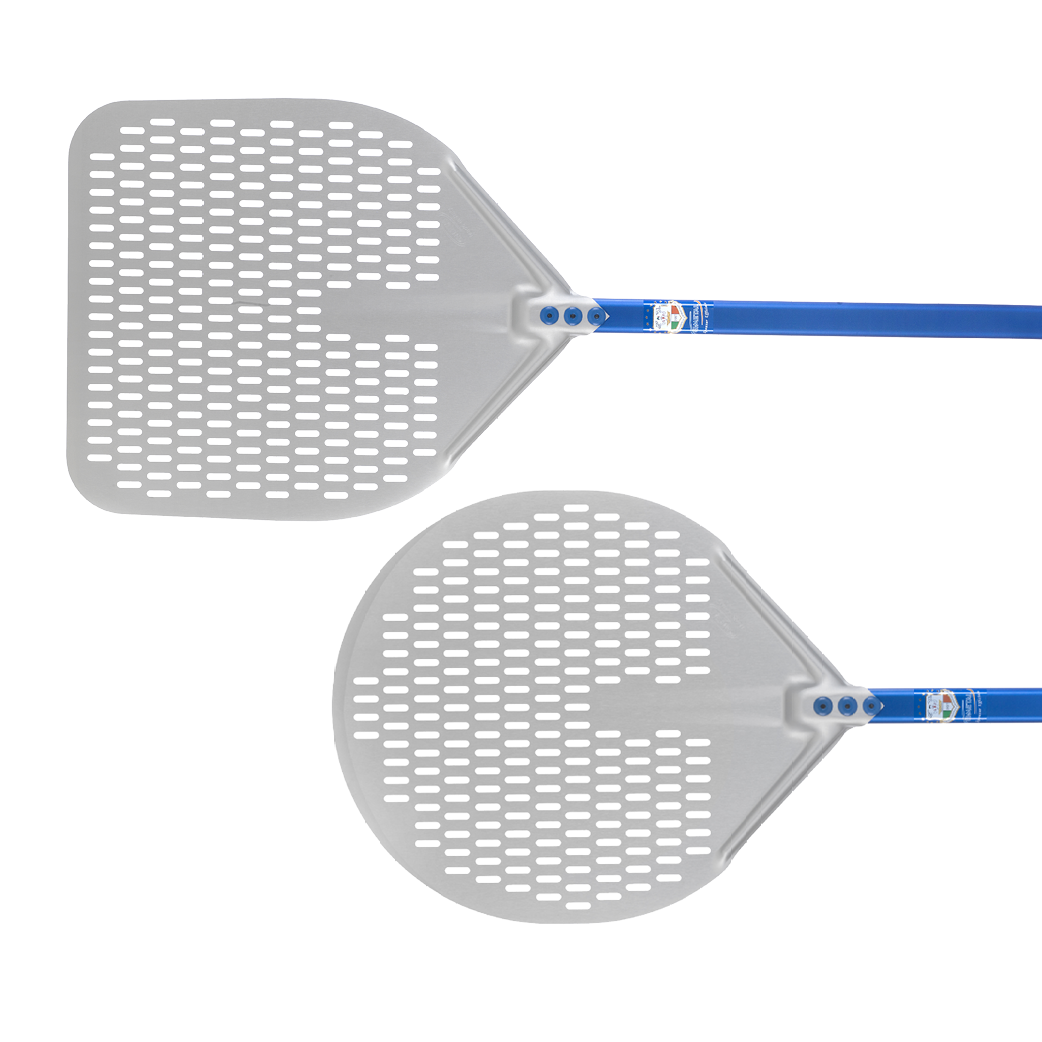

Rectangular or round?

The rectangular peel is the traditional choice: it features a larger contact surface with the pizza on the front side, due to its milling.

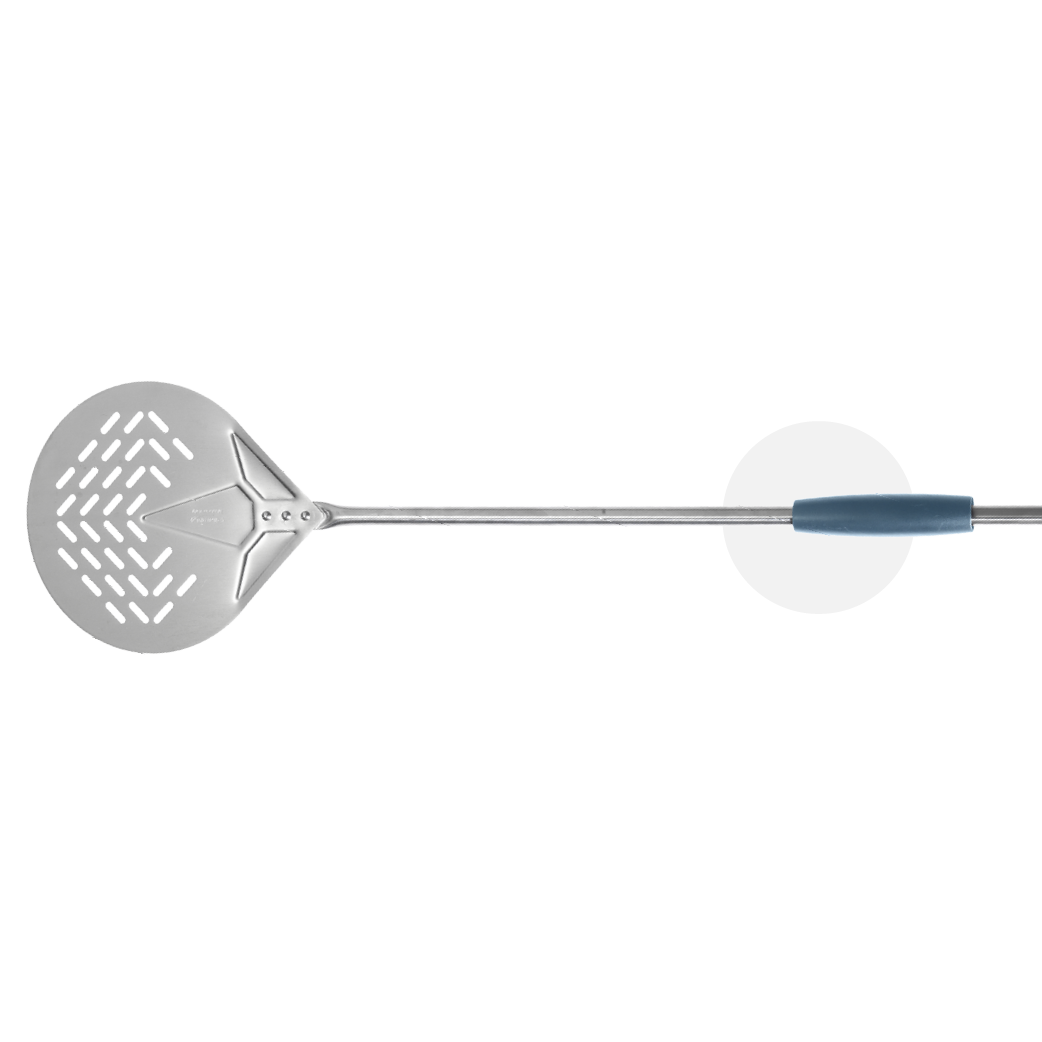

The round peel features a widened runner with a smooth and regular milling on a wide extension of the curvature and allows the pizza maker to take the pizza from the side, and not only from the front of the peel. Plus, having no corners makes it easier to place the pizzas next to each other inside the oven, to correctly move them.

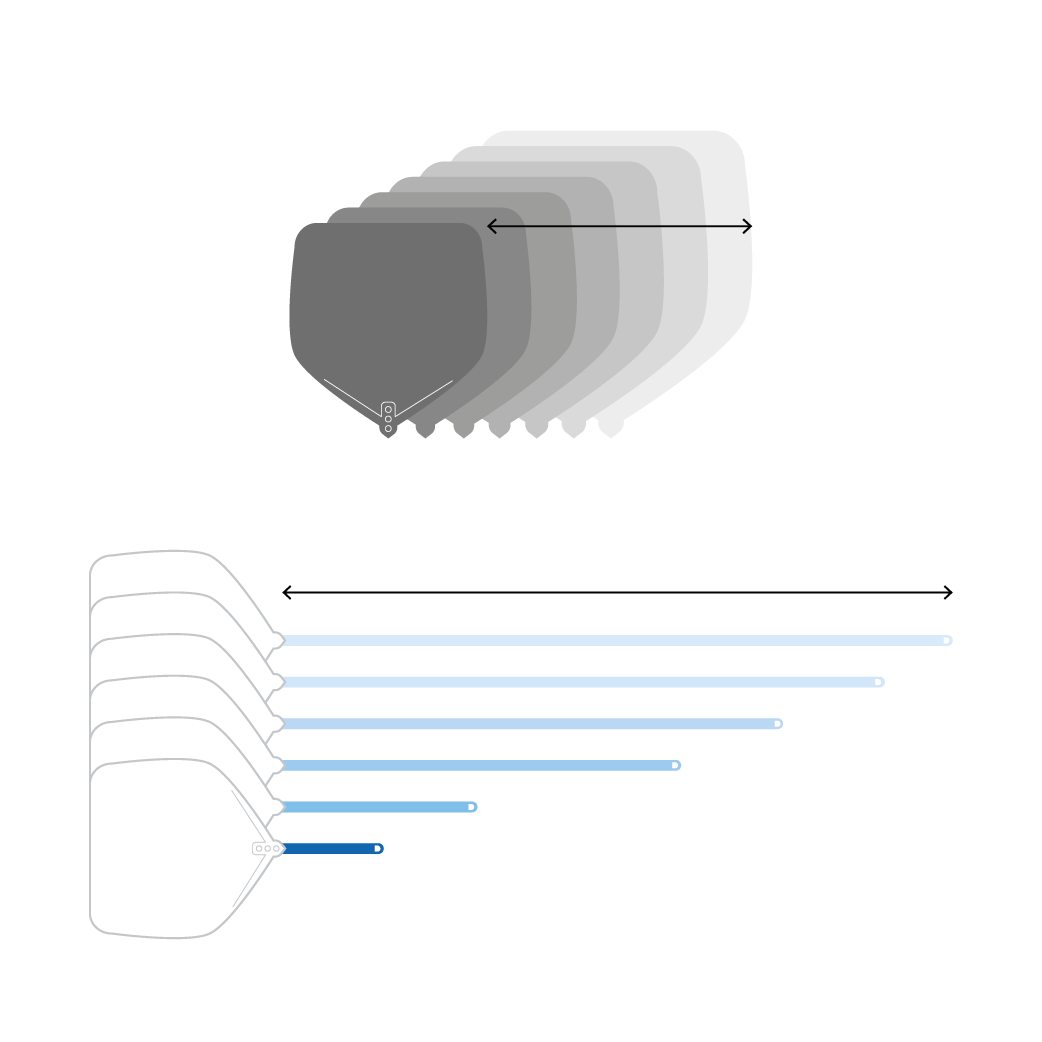

A size for every need

The type of pizza, the workspace available and the size of the oven used are essential elements to choose the pizza peel that reflects and respects your needs. The diagrams shown are a valid aid to see the difference between the different sizes available, that can help you to evaluate and choose the product.

MATERIALS: STEEL OR ALUMINIUM?

What are the pros and cons of these three different materials which a pizza peel is made of? Let's take a closer look:

Steel pizza peels Unlike wood, steel peels last longer and are smoother and sturdier: they are capable of withstanding impact between the work surface and the oven. On the other hand, their specific weight is heavier than aluminum. The steel used for Gi.Metal pizza peels is strictly stainless, of European origin, with a low percentage of nickel to respect those who suffer from allergies.

Aluminum pizza peels Gi.Metal pizza peels are mainly made of anodised aluminium. Anodising is a chemical process on aluminum enhancing the natural properties of the raw material, with the following advantages:

• Greater resistance to corrosion

• Harder surface

• Better resistance to wear and abrasion

• Gives the peel a pleasant appearance, uniform and long-lasting

Anodised aluminum. Which to choose?

Ever-growing market requirements led us to be specialised in these studies, which after years of extensive research, analyses and tests, we meet the demand with different types of anodising:

Neutral Anodising: Azzurra, Napoletana, Alice

Hard Anodising: Carbon, Evoluzione

Golden Hard Anodising G.H.A.: Gold

The importance of the 3 rivets

The most delicate area of each pizza peel is the junction point between the peel head and handle. To guarantee never before seen safety and stability, Gi.Metal makes use of special rivets used in aviation to assemble airplanes; we use 3, in line, a distinctive mark of the brand that makes our pizza peels unique and unmistakable.

The 3-rivet pizza peels belong to the following Lines: Carbon, Gold, Evoluzione, Azzurra and Napoletana.

SPATULA EFFECT. HOW TO ACHIEVE IT?

The flexibility of the peel head together with front milling provide the spatula effect: the peel bends exactly in the middle creating perfect adherence between the peel and the work surface making it easier to pick up the pizza. The central ribbing stiffens the head and together with side ribbing allows supporting heavy loads.

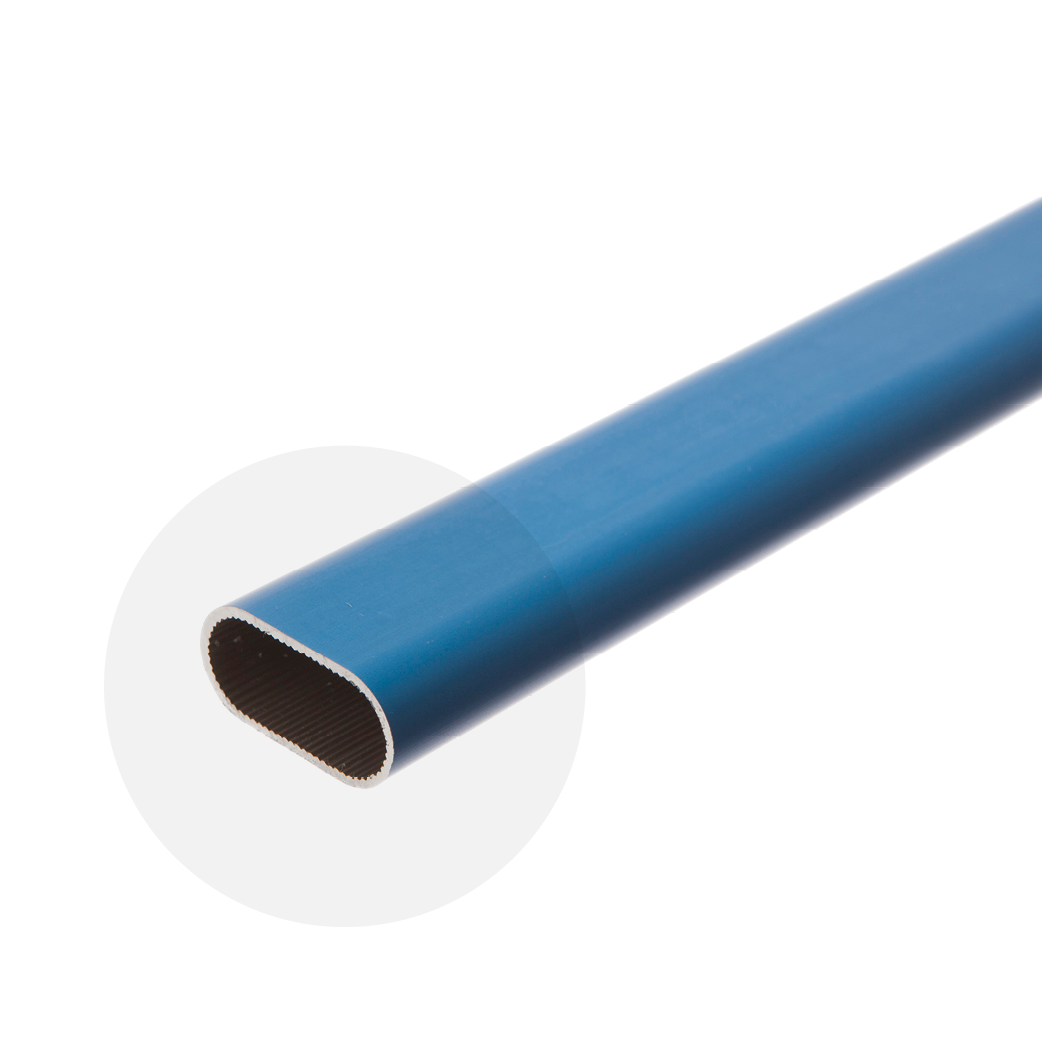

The benefit of ergonomic handles

The aluminum handles are lightened and reinforced with a particular process that creates lengthwise ribbing on the handle as shown by the internal knurling. The particular oval tubular shape makes it more stable, keeping it from rotating.

Gi.Metal small peels. How are they designed?

The solid and lightweight small peel is available in solid head versions or with different types of perforation. It is made entirely of stainless steel, to prevent the transmittance of heat from the oven. The handle base and intermediate sliding grip are made with specific high density polymer, making them shock and heat resistant. This perfectly protects your hands from heat and allows the intermediate element to slide smoothly. The specific interlock on the handle base blocks the intermediate element, so it is at the top when the small peel is placed upside down.

Our products

Q UALITY, PASSION AND INNOVATION ARE THE VALUES THAT GUIDE GI.METAL. THE STUDY AND ANALYSIS OF THE END CUSTOMERS’ NEEDS, CONSTANT RESEARCH FOR INNOVATIVE MATERIALS, THE HIGH QUALITY OF THE SERVICES OFFERED: THESE ARE THE PRINCIPLES THAT HAVE MADE THE GI.METAL PIZZA PEEL KNOWN AND APPRECIATED BY MILLIONS OF PIZZA MAKERS, BECOMING AN ESSENTIAL TOOL IN PIZZERIAS WORLDWIDE.

Over thirty years of experience have allowed us to refine the characteristics of the products we make. But this does not stop us from looking forward and exploring new solutions. The constant search for innovative materials, the attention for and investment in resources, to achieve ever more refined and groomed processes allow us to gradually and continuously improve the products, reaching that excellence which Gi.Metal is proud of.

Professional pizza peels

We supply a wide range of pizza peels to put the pizza in the oven and small peels to take it out.. We are the first company to have designed and made the perforated pizza peels, which shake off excess flour before putting the pizza in the oven. Gi.Metal has developed nine different production lines, each with specific characteristics:

Carbon Line

A technological material like carbon meets aluminum providing the instrument with lightness, nobility and emotion by using a high-tech material with a flawless finish.

Gold Line

G.H.A (Golden Hard Anodising) is a highly innovative treatment to protect and reinforce the peel, a special exclusive Gi.Metal process that makes the peel surface extremely resistant to heat, corrosion, scratches and wear with incomparable smoothness and a high anti-bacterial and anti-mould capacity.

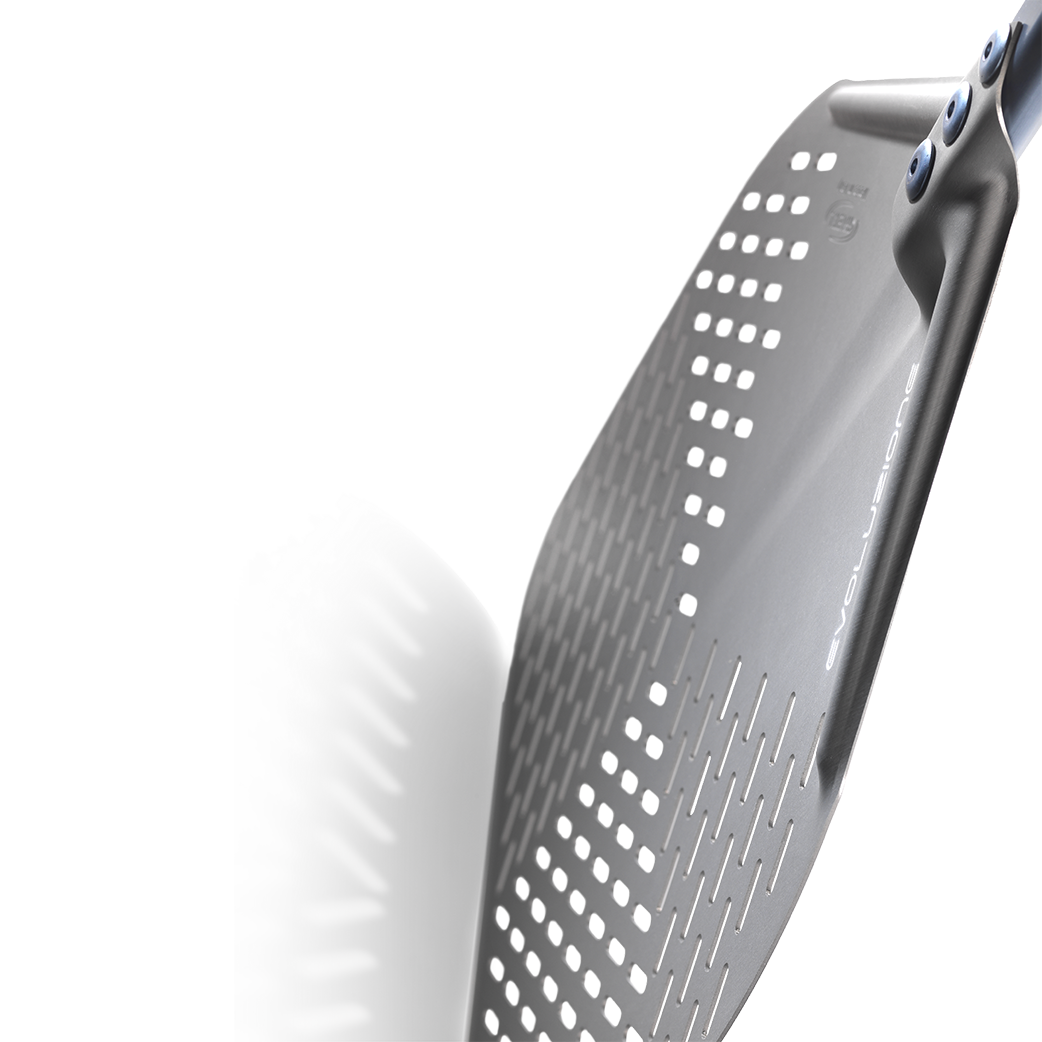

Evoluzione Line

The Evoluzione line adds a new perforation and particularly neat design to the flexibility and lightweight features of the Azzurra line. The new pattern of the holes enhances performance in terms of smoothness and shaking flour off, while the new aesthetic details give it style and elegance. S.H.A. (Special Hard Anodising) treatment provides the utmost performance in terms of heat resistance, smoothness and long life.

Azzurra Line

A complete line whose peels are characterised by lightweight, extreme resistance and flexibility. There is a wide variety capable of meeting all the needs of professional pizza makers: rectangular, round and by-the-meter, smooth, perforated and relief surfaces, handles of different lengths, in different materials and for different types of ovens.

Napoletana Line

A line designed to meet the requirements of pizza makers who make pizza according to the Neapolitan style, , therefore in ovens at very high temperatures and with the maximum frequency of use. Upgraded material, special circular holes and a laser incision make the tools one-of-a-kind.

Alice Line

A classical line, inspired by the more traditional concept of the pizza peel: with the unique shape, rectangular with very wide corners, a perfect synthesis between round and rectangular, the structure is stronger and more rigid, with a thicker handle and head.

Amica Line

A line designed for home use for those who occasionally use their pizza oven and look for quality, lightweight and manageable utensils.

OTHER PIZZERIA UTENSILS

In addition to pizza peels, our company also produces and is specialized in other professional utensils the pizza maker needs: from instruments for cleaning (oven brushes), preparation (dough cutter, spatulas, spoons and ladles, boxes, etc.) to those for baking (nets, pans, pliers etc.), cutting (wheels, knives, scissors etc.) serving (trays, buckets, cutting boards etc.)